Product Details:

One Characteristics of cycloidal pinwheel reducer

The cycloidal pinwheel reducer is a new type of transmission machinery designed according to JB/T2982-94 using cycloidal pinwheel meshing and the principle of planetary transmission with few tooth differences. It has been widely used in various fields such as petrochemicals, construction, metallurgy and mining, lifting and transportation, textile printing and dyeing, engineering machinery, food industry, electronic television, etc., and is highly trusted and praised by users

The cycloidal pinwheel reducer has the following characteristics:

1. Large transmission ratio: The single-stage transmission ratio is 9-87. The two-stage transmission ratio is 99-7569, and the transmission ratio can be larger when multiple stages are connected in series;

2. High transmission efficiency: The single-stage transmission efficiency is above 90%;

3. Compact structure: small size, light weight, high-speed shaft and low-speed shaft on the same axis, easy to assemble and disassemble;

4. Smooth operation with low noise, able to withstand overload and impact;

5. Reliable use and long lifespan.

2、 Model and specifications of cycloidal pinwheel reducer

1. Type:

The BW cycloidal pinwheel reducer is a foot plate type, dual axis type, and horizontally installed;

The BL cycloidal pinwheel reducer is a flange type, dual axis type, vertical installation;

The BWY cycloidal pinwheel reducer is a foot plate type, dedicated asynchronous motor direct connection type, horizontally installed;

BLY cycloidal pinwheel reducer is a flange type, dedicated asynchronous motor direct connection type, vertically installed;

BWD foot type horizontal mounted ordinary motor direct coupled cycloidal pinwheel reducer;

BLD flange mounted ordinary motor direct coupled cycloidal pinwheel reducer.

2. Model of cycloidal pinwheel reducer:

3. Transmission ratio

Any single-stage transmission ratio that can be provided can be combined with a two-stage one. If you need transmission ratios not listed in the table, please contact our factory.

4. Marking examples

Table 2. Special Structural Installation Forms

Note: If the user needs to install a special motor, please specify the motor model in the contract;

If the user requires a special structural form, please indicate it in the contract or attach a schematic diagram of the structural form.

3、 Transmission ratio, input power, and output torque table of two-stage cycloidal pinwheel reducer (working condition coefficient K=1)

4、 Selection instructions for cycloidal pinwheel reducer

This series of cycloidal pinwheel reducers is designed for continuous operation in one direction for eight hours a day under stable load conditions. When the actual working time and load properties of the reducer do not match the above design conditions, the working condition coefficient KA should be used for correction. KA is determined according to the following table.

Work situation coefficient KA table

Note: (1) The maximum instantaneous load or starting load shall not exceed 160% of the rated load hormone.

(2) When the prime mover is a multi cylinder engine, the working conditions and load properties in the data table can be selected as K=1.0-1.7

(3) When the prime mover is a single cylinder engine, the working conditions and load properties in the data table can be selected as K=1.2-1.8

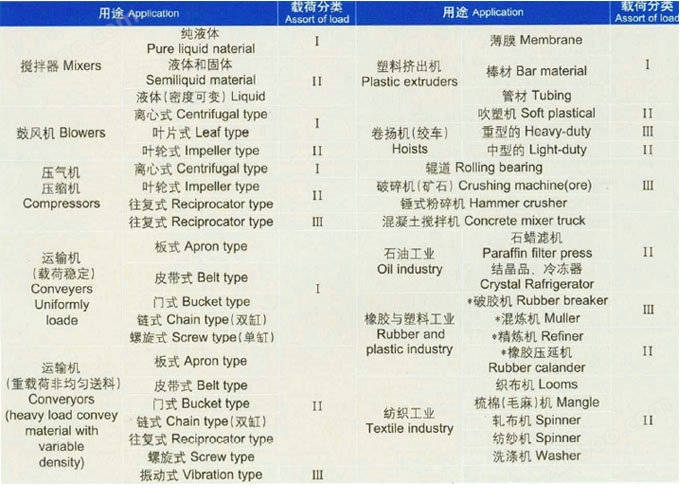

Reference Table for Classification of Gearbox Usage and Load Properties:

The selection of cycloidal pinwheel reducer can be divided into the following situations:

When the input shaft speed of the reducer is equal to the rated speed of the standard reducer, select according to the following formula:

When selecting the machine model based on the output shaft torque of the reducer, the general stable load and short-term instantaneous load should not exceed 160% of the stable load hormone. The following formula should be used for selection:

When the input speed of the reducer is not equal to the rated speed in the load capacity table, the machine model should be selected first based on TC being less than or equal to TP

If the input speed is variable (when driven by a variable speed motor or transmission device), it should be determined according to the usage conditions. If a constant power is required, the machine model should be selected based on the lowest speed. If a constant torque is required, the machine model should be selected based on the highest speed (paying attention to the operating condition coefficient and efficiency loss when selecting).

5、 The use and lubrication of cycloidal pinwheel reducer

(1) , Use

1 This machine is suitable for continuous operation and allows for forward and reverse rotation;

2. The output shaft of a single-stage reducer rotates in the opposite direction to the input shaft, while the output shaft of a two-stage reducer rotates in the same direction as the input shaft. The output shaft of the three-stage reducer rotates in the opposite direction to the input shaft;

3 The output shaft of this reducer cannot withstand axial force;

When the output shaft and input shaft are matched with other parts, direct hammering is not allowed to prevent damage;

5. The keys on the output shaft and input shaft extension shall be selected according to the standard flat key type ruler (GB1096-79), and the fitting tolerance value of the stop diameter D4 of the vertical reducer output end machine base shall comply with the limit and fitting (GB1801-99) H9 regulations;

When using a coupling, the axis of the working machinery and the motor should be concentric, and the installation error of the reducer should not exceed the allowable error value of the coupling used;

7. The reducer can rotate flexibly by hand after installation;

8. Horizontal dual axis reducers generally operate with the output shaft axis line in a horizontal position; When tilted for use, the elevation angle of the axis should not exceed 15 degrees (with the output shaft extending downwards);

9. Vertical reducers should be used with the output shaft extending vertically downwards;

10. After installation, the reducer must undergo a trial run before formal use, and gradually load and operate under normal idle conditions;

11. When the load is large and the starting frequency is high, the machine base and foundation should be equipped with positioning pins or optional hydraulic couplings.

(2) Lubrication

1. This machine mainly uses oil bath lubrication

Suitable for ambient temperatures ranging from -10 ° C to 40 ° C: N46 and N68 lubricating oils are available at ambient temperatures ranging from -10 ° C to 0 ° C; When the temperature is between 0 ° C and 40 ° C, N68, N100, N150, N220 lubricating oil should be used. When installed at an angle, grease lubrication can be used. Vertical BL27 and XL7 and above have circulating lubrication: before starting the oil pump micro motor, check whether the oil pump is supplying oil. Otherwise, the micro motor wiring should be swapped. As the oil pump operates in the specified direction, the oil level should be maintained at the center line of the circular oil mark after the oil pump is in normal operation. There is an "O" - shaped sealing ring at the connection between the oil pump and the reducer end face to prevent oil leakage.

2. Oil change system

After the first refueling operation for two weeks, the oil should be replaced with new oil and the internal oil stains should be washed away. It can be replaced every 3-6 months thereafter. If the ambient temperature is high and humid, the oil change time should be shortened appropriately. During operation, the oil level in the gearbox body must be maintained at the specified height, and should not be too high or too low. Rotate the ventilation cap on the engine seat or flange to replenish the oil

6、 Appearance and installation dimensions of XLE (D) two-stage cycloidal needle thread reducer